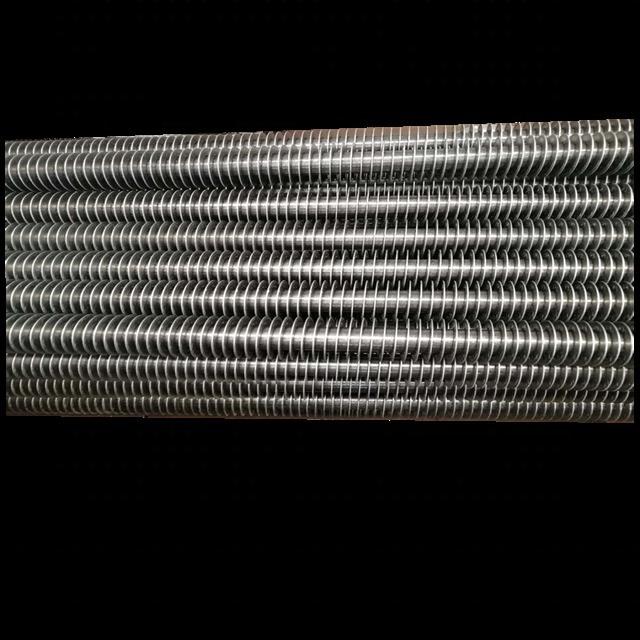

Vòng xoắn ốc bằng thép không gỉ / thép carbon cho máy tiết kiệm nồi hơi và máy làm nóng trước không khí

Các ống có vây loại H được thiết kế để thu hồi nhiệt thải từ khí thải khói trong nồi hơi nhà máy điện, nồi hơi công nghiệp, lò nung và nhà máy điện biển.cải thiện hiệu quả nhiên liệu, và giảm phát thải trong khi phục vụ như các yếu tố trao đổi nhiệt được tăng cường ở phần đuôi của hệ thống ống dẫn nhiên liệu.

Bụi có vây kiểu H đôi có cấu trúc riêng biệt sáng tạo ngăn ngừa sự tích tụ tro và các vấn đề chống khí phổ biến trong các ống có vây xoắn ốc.Thiết kế xương sườn ballast của nó tăng cường rung động dưới dòng không khí xung, tạo thuận lợi cho việc loại bỏ tro hiệu quả.

Lợi ích chính bao gồm bề mặt sưởi ấm mở rộng để cải thiện hệ số truyền nhiệt và chức năng tự làm sạch giảm thiểu sự lắng đọng bụi khói, tắc nghẽn,và mặc - đảm bảo tuổi thọ kéo dài và hoạt động an toàn của nồi hơi nhiệt thải.

Thông số kỹ thuật sản phẩm

| Mô tả |

Máy tiết kiệm nồi hơi, nồi hơi hơi, nồi hơi dầu, nồi hơi than, nồi hơi khí |

| Vật liệu |

Thép hợp kim, thép carbon, SA210C, SA213T22 |

| Tiêu chuẩn |

ASME, GB, EN |

| Quá trình chính |

H pin hàn |

Hồ sơ nhà sản xuất

Zhangjiagang Hua Dong Boiler Co., Ltd, được thành lập vào năm 1985, chuyên sản xuất nồi hơi nhà máy điện, nồi hơi công nghiệp, HRSG, nồi hơi đốt chất thải,nồi hơi sinh khối và các thành phần bề mặt sưởi ấm liên quanChúng tôi cung cấp các dịch vụ toàn diện từ thiết kế và sản xuất để lắp đặt và bảo trì.

Lợi ích của chúng ta

38 năm kinh nghiệm trong ngành

Với gần bốn thập kỷ nghiên cứu, phát triển và sản xuất, chúng tôi duy trì năng lực sản xuất đáng kể để đáp ứng nhu cầu toàn cầu.

Hệ thống kiểm soát chất lượng

- Báo cáo kiểm tra va chạm và tính toán độ bền với tài liệu vật liệu đầy đủ

- 100% kiểm tra không phá hủy (NDT) các tấm, ống và điện cực thép

- Kiểm tra hàn toàn diện bao gồm xét nghiệm tia X, tia γ và chất thâm nhập chất lỏng

- Kiểm tra áp suất thủy lực để xác minh các tiêu chuẩn áp suất làm việc và an toàn

Hệ thống đảm bảo chất lượng hoàn chỉnh của chúng tôi tuân thủ các tiêu chuẩn quốc tế,đảm bảo tất cả các quy trình sản xuất và sản phẩm cuối cùng đáp ứng các yêu cầu hợp đồng nghiêm ngặt và các quy định quốc gia thông qua các giao thức kiểm tra nghiêm ngặt.

Giấy chứng nhận

ISO 9001:2015

Giấy chứng nhận CE

EN ISO 3834-2

ASME với S, U & NB Stamps

Phân phối trên toàn thế giới

Câu hỏi thường gặp

Q1: Thời gian bảo hành là bao lâu?

Chúng tôi cung cấp bảo hành 18 tháng cho tất cả các phụ tùng thay thế (không bao gồm các thành phần mong manh).

Q2: Làm thế nào bạn đảm bảo chất lượng?

- Tuân thủ nghiêm ngặt các yêu cầu hệ thống ISO và CE

- Sản xuất thủ công chuyên nghiệp với kiểm soát chất lượng chuyên dụng ở mỗi giai đoạn

- Theo dõi sản phẩm toàn diện thông qua hệ thống quản lý của chúng tôi

Q3: Bạn cung cấp sản phẩm gì?

Các nồi hơi CFB, nồi hơi HRSG, nồi hơi tiết kiệm, ống vây, máy làm nóng trước không khí, máy làm nóng siêu, tường màng, đầu đa dạng và các thành phần áp suất khác.

Q4: Bạn cung cấp dịch vụ gì?

Trước khi bán:

Thông tin sản phẩm, nghiên cứu thị trường, tùy chỉnh, tư vấn xử lý và các dịch vụ hỗ trợ khác.

Sau bán hàng:

- Đào tạo kỹ thuật theo yêu cầu của khách hàng

- Các sản phẩm thay thế bảo hành

- Cung cấp phụ tùng phụ tùng bảo trì

- Theo dõi khách hàng thường xuyên

- Trả lời nhanh chóng các thắc mắc và khiếu nại

Điều khoản giao hàng:FOB, CFR, CIF, EXW, FCA

Tùy chọn thanh toán:T/T, L/C, MoneyGram, Western Union, Tiền mặt

Tiền tệ:USD, CNY

Ngôn ngữ:Tiếng Anh, Trung Quốc

Q5: Bạn là một nhà máy hoặc công ty thương mại?

Chúng tôi hoạt động như một cơ sở sản xuất nằm chỉ 130km (2 giờ đi xe) từ sân bay Thượng Hải. Chúng tôi cung cấp dịch vụ đón từ Thượng Hải cho khách hàng đến thăm.